Motorcycle Handlebar Types

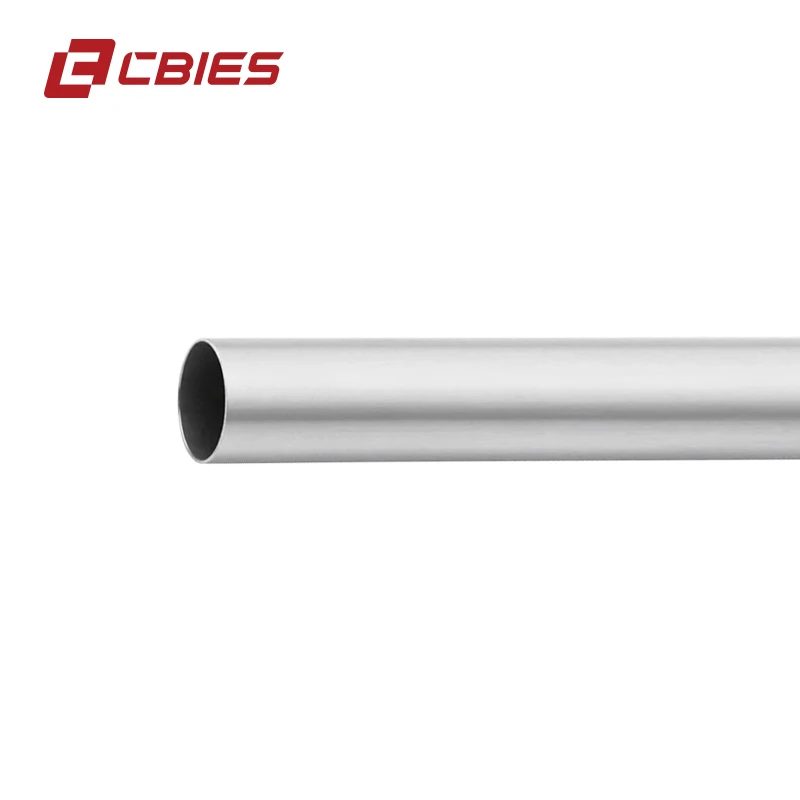

When it comes to customizing your motorcycle, choosing the right handlebars is crucial for both comfort and style. Among the various types available, straight motorcycle handlebars have gained significant popularity among riders seeking a blend of practicality and aesthetics.

Straight motorcycle handlebars, as the name suggests, feature a uniform horizontal design that is devoid of any upward or downward bends. This simplicity in design not only offers a classic look but also contributes to a more comfortable riding posture, especially for those who prefer a relaxed seating position. One of the significant benefits of straight handlebars is their ability to provide a wide grip, which enhances control and stability while riding.

In addition to comfort and control, straight motorcycle handlebars are versatile and can be installed on various bike models, from cruisers to choppers. This adaptability makes them an appealing choice for custom builders and enthusiasts looking to create a unique riding experience. Moreover, the straightforward design allows for easier installation and maintenance, a key consideration for many riders who enjoy DIY projects.

It's important to note that riders should consider their personal riding style and ergonomic needs when selecting handlebars. While straight motorcycle handlebars offer a distinctive aesthetic and practical advantages, the right choice will ultimately depend on individual preferences regarding reach and comfort. Additionally, some riders may find that they prefer the feel of slightly higher or angled handlebars, which can impact handling and overall ride experience.

In conclusion, straight motorcycle handlebars stand out as an excellent option for riders seeking enhanced comfort and control. Their timeless design, coupled with versatility and ease of use, makes them a top choice in the realm of motorcycle customization. Whether you're looking to revamp your current setup or build a bike from scratch, considering the type of handlebars is essential for an optimal riding experience.

Why Straight Motorcycle Handlebars Are Perfect for Custom Builds

Straight motorcycle handlebars are a popular choice for custom motorcycle builds due to their simplicity, versatility, and the ease with which they can be tailored to suit unique rider preferences. The use of precision steel tubes is central to creating high-quality, custom-made straight handlebars, offering exceptional flexibility and accuracy in design.

Precision steel tubes are ideal for custom builds because they can be easily manipulated into various shapes and sizes, allowing for handlebars that perfectly match the rider's ergonomic needs and aesthetic desires. Steel tubing offers a high level of structural integrity while maintaining the ability to be bent and shaped with incredible accuracy. This ensures that custom handlebars not only look great but also perform optimally, providing the rider with the ideal control and comfort.

The flexibility of steel tubes allows for customization in terms of length, width, and height, which are essential factors in determining the riding position. Whether a rider prefers a more upright, relaxed position or a forward-leaning, aggressive stance, precision steel tubing allows the handlebars to be manufactured to meet these exact specifications. The steel’s strength also means that these custom handlebars can withstand the stress of aggressive riding without compromising safety.

Moreover, precision steel tubes offer superior resistance to wear and corrosion, ensuring that custom handlebars remain durable and functional over time. This is particularly important in custom builds, as the handlebars are often exposed to a variety of environmental conditions, from extreme temperatures to moisture.

In summary, straight motorcycle handlebars made from precision steel tubes are the perfect choice for custom builds due to their versatility, durability, and precision. Steel tubing allows builders to craft handlebars that are tailored to both the rider’s style and performance requirements, making it an essential material for any bespoke motorcycle project.

Straight Motorcycle Handlebars FAQs

What are straight motorcycle handlebars?

Straight motorcycle handlebars are a type of handlebar with a simple, horizontal design. Unlike other handlebars that may feature curves or rises, straight handlebars extend straight across the front of the motorcycle, providing a wide, stable grip. They are commonly used in cruiser motorcycles, custom builds, and certain sportbikes for their straightforward design and ergonomic benefits.

Why are straight handlebars preferred in custom motorcycle builds?

Straight handlebars are often chosen in custom motorcycle builds because of their clean, minimalist design and versatility. They allow builders to tailor the width, height, and grip position to the rider’s preferences. Additionally, the simple design makes them easier to modify, giving custom builders full control over the aesthetics and functionality of the bike.

What materials are straight motorcycle handlebars made from?

Straight motorcycle handlebars are commonly made from materials such as steel, aluminum, or titanium. Steel is particularly popular because it offers strength, durability, and flexibility. Precision steel tubes are often used in high-quality handlebars because they can be easily shaped and bent while maintaining the necessary strength to handle stress and wear.

What is the advantage of using precision steel tubes for straight handlebars?

Precision steel tubes offer several advantages for straight motorcycle handlebars. They allow for exact control over the thickness, strength, and flexibility of the handlebars, which is essential for custom designs. Steel tubing can be easily bent to precise angles, enabling builders to create handlebars that are tailored to specific rider needs, while also offering durability and resistance to corrosion over time.

How do I know if straight handlebars are right for me?

Choosing the right handlebars depends on your riding style and comfort preferences. Straight handlebars tend to offer a more relaxed and comfortable riding position, making them ideal for cruiser and custom bikes. However, if you’re seeking a more aggressive riding posture or performance-oriented control, other handlebars like clip-ons or ape hangers may be better suited. Test riding different handlebars can help you decide which feels most comfortable for you.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu