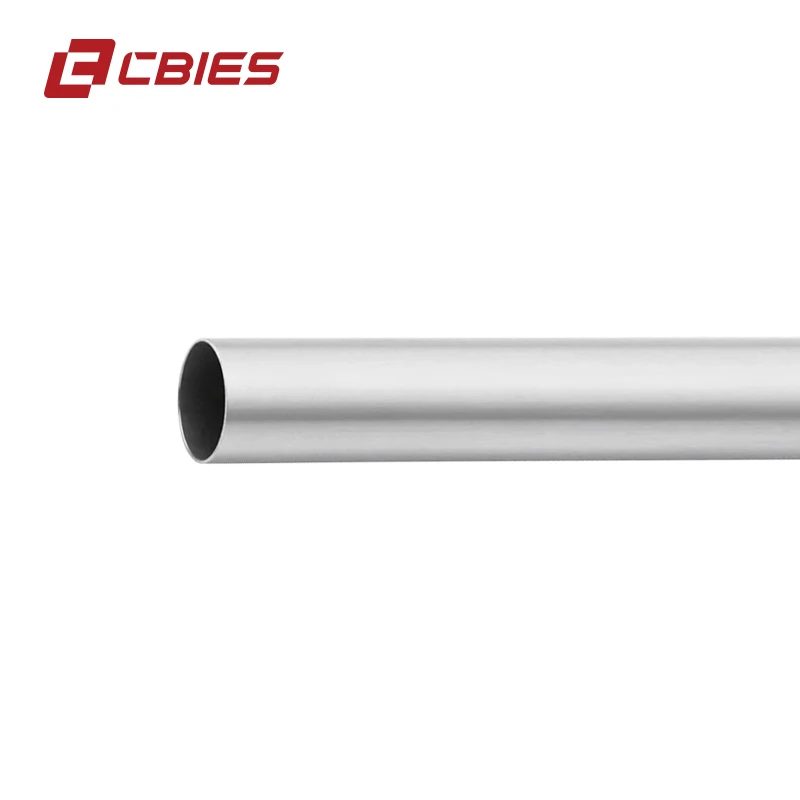

Why Choose Coated Aluminum Tubing for Cars and Vehicles?

In the automotive industry, the choice of materials significantly influences performance, safety, and longevity. One standout option is coated aluminum tubing. This specialized material offers a range of benefits that make it particularly favorable for cars and vehicles.

Firstly, coated aluminum tubing boasts an exceptional strength-to-weight ratio. Unlike traditional steel tubing, which can be heavy and cumbersome, aluminum provides a lightweight alternative that improves fuel efficiency. Vehicles incorporating this material can achieve better mileage, thus contributing to cost savings for consumers. The reduced weight also enhances overall handling and performance, making it an ideal choice for modern automotive designs.

Additionally, the coating on aluminum tubing plays a critical role in extending its lifespan. The protective layer guards against corrosion, which is a common issue in vehicles exposed to harsh environments. With coated aluminum tubing, vehicles can resist oxidation and corrosion, leading to lower maintenance costs and increased durability over time. This is especially pertinent for regions with high humidity or road salt exposure.

Moreover, coated aluminum tubing offers excellent thermal conductivity. This feature is crucial for fluid transport systems in vehicles, as it helps maintain optimal operating temperatures for components such as radiators and heat exchangers. Efficient heat management is vital for performance and overall engine reliability.

Lastly, the versatility of coated aluminum tubing allows for various applications, from structural components to exhaust systems. Its adaptability ensures that it meets the diverse needs of automotive parts factories while providing aesthetic appeal with its sleek finish.

In conclusion, choosing coated aluminum tubing for cars and vehicles is a strategic decision. Its blend of lightweight properties, resistance to corrosion, thermal efficiency, and versatility makes it an outstanding choice for contemporary automotive applications. Investing in this innovative material can enhance performance, reduce costs, and ensure vehicles stand the test of time.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu