Our Factory improves the manufacturing ability of Precision Steel Tubes.

Jun . 17, 2024 15:00

Our factory improves its precision steel tube manufacturing capacity

From June 12 to 15, 2024, the business department, project department, marketing department, and quality inspection department of CBIES visited the factory and communicated with the factory production department on product production technology and testing technology. Through this study, CBIES will reach new heights in production capacity, technology, and product versatility.

Factory Overview

Our factory stands at the forefront of technological advancement and specializes in manufacturing precision steel tubes for high-end applications such as automotive parts and furniture. Our strategic focus has always been on improving productivity and ensuring environmental sustainability and ethical practices, as seen from its adaptive work schedule under peak temperatures.

Increased Capacity

Our factory has invested in expanding its production capacity through state-of-the-art machinery and streamlined processes. At this stage, we have 8 production lines, including 3 headrest tube production lines and 3 large tube (lift table) production lines, as well as 2 medium-sized tube (seat tube) production lines. Covering an area of 50 acres, the total annual production of steel reaches 50,000 tons.

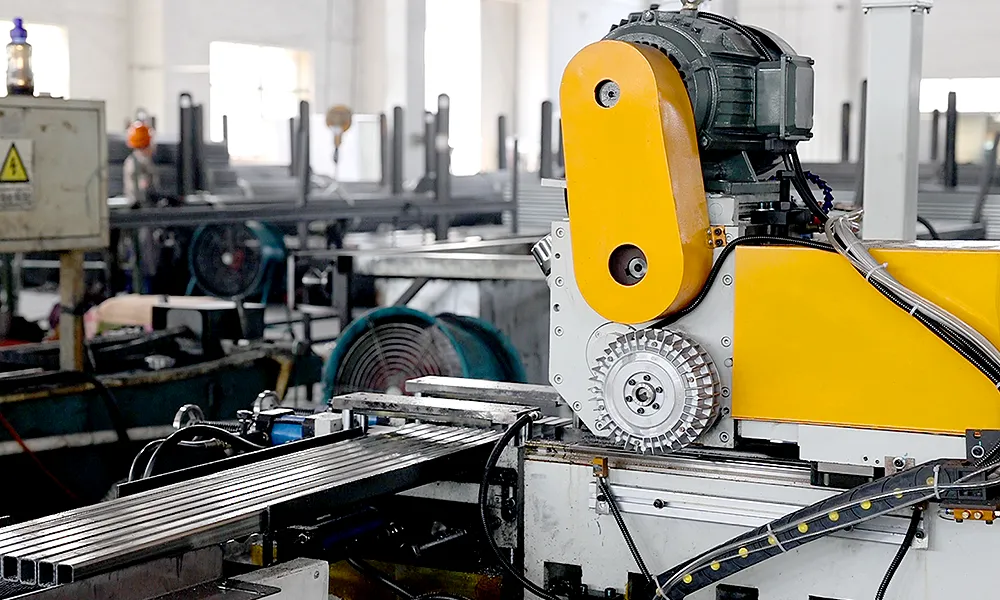

Introduction of Advanced Equipment and Process Innovation

This time with the production department, we implemented dedicated production lines for specialized products such as headrests and seat tubes. This strategic move strengthened quality control and accelerated production cycles. Our use of Taiwan-made bending machines ensures meticulous bending accuracy, while laser and high-pressure punching operations enable precise punching, contributing to the superior finish of our products. The introduction of advanced robotic welding systems has greatly reduced labor requirements while improving efficiency and safety. This upgrade complements our existing cutting-edge Japanese machines, allowing tighter tolerances, such as ±0.5mm in seat tube length, demonstrating our commitment to precision.

Product Features and Competitive Advantages

Our steel tubes stand out for their unique characteristics, making them suitable for demanding industries. For example, our aluminum-coated tubes are both flexible and have excellent corrosion resistance, making them ideal for automotive exhaust systems, industrial equipment, and natural gas pipelines. In addition, we are able to produce thick-walled tubes up to 3.5mm thick and irregularly shaped tubes to meet complex structural needs, such as dashboards and windshield brackets.

Diversification into the automotive and high-end furniture sectors

Our factory has expanded its footprint in the automotive and high-end furniture markets, offering solutions ranging from complex headrest components to sturdy structures for ergonomic office and home furniture. By leveraging versatile materials such as Q235, ST37, and HC series steels, we meet a wide range of customer needs, backed by flexible MOQs and responsive pricing strategies.

Customer Complaint Handling Protocol

We understand the importance of customer satisfaction and have therefore improved our complaint handling process. Inspired by best practices, we now implement a rigorous inspection process, including a comprehensive inspection before packaging, to mitigate issues of surface defects and dimensional inconsistencies. If a delivery is short, we correct it quickly without the need for extensive audits, saving time and ensuring customer satisfaction.

Environmental, Social and Governance (ESG) Commitment

Recognizing the environmental and social impacts of manufacturing, our factory has taken responsive measures to adjust working hours during periods of extreme heat to ensure worker welfare. This approach is in line with our broader ESG goals and reflects our dedication to sustainable and responsible manufacturing practices.

The insights gained through this in-depth study with the factory-inspired our factory's approach to manufacturing precision steel tubes. With enhanced production lines, cutting-edge technology, and a meticulous focus on product quality and customer service, we are poised to deliver solutions that meet and exceed the expectations of the most discerning customers in the automotive, and high-end furniture industries. As we continue to integrate these learnings, we will continue to combine craftsmanship and innovative technologies in precision manufacturing, fostering growth and innovation in every area we supply.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu