CNC motorcycle parts supplier

Jun . 16, 2024 10:41

The Vital Role of CNC Motorcycle Parts in the Automotive Industry

In the fast-paced world of automotive manufacturing, precision and efficiency are paramount. This is especially true for the motorcycle industry, where every component plays a crucial role in the performance and safety of the vehicle. Among the various technologies that have revolutionized this sector, Computer Numerical Control (CNC) stands out as a game-changer. CNC motorcycle parts have not only elevated the standards of production but also transformed the way motorcycles are designed and maintained.

CNC technology involves the use of computers to control machine tools, enabling highly accurate and complex machining operations. When it comes to motorcycle parts, CNC systems can produce everything from engine components to intricate bodywork with unparalleled precision. This level of accuracy significantly reduces the need for manual adjustments and decreases the likelihood of errors that could compromise the bike's functionality or safety.

One of the most significant benefits of CNC motorcycle parts is their consistency. Each part produced by a CNC machine is an exact replica of the previous one, ensuring that every motorcycle leaving the assembly line meets the same high standards. This consistency extends beyond mere dimensions; it encompasses tolerances, finishes, and overall quality, making for a more reliable final product.

The efficiency of CNC manufacturing cannot be overstated. These machines can operate continuously, 24/7, with minimal human intervention These machines can operate continuously, 24/7, with minimal human intervention

These machines can operate continuously, 24/7, with minimal human intervention These machines can operate continuously, 24/7, with minimal human intervention

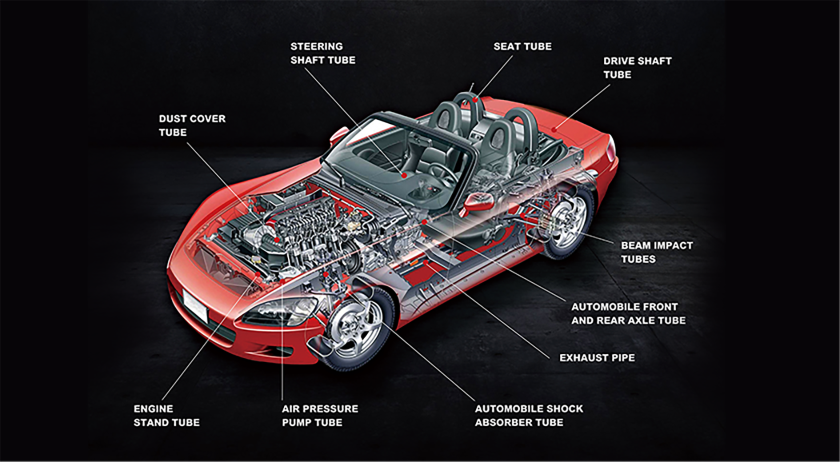

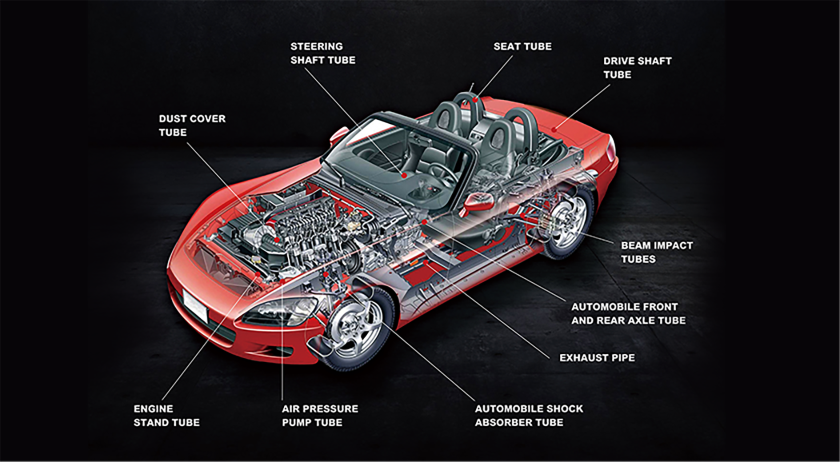

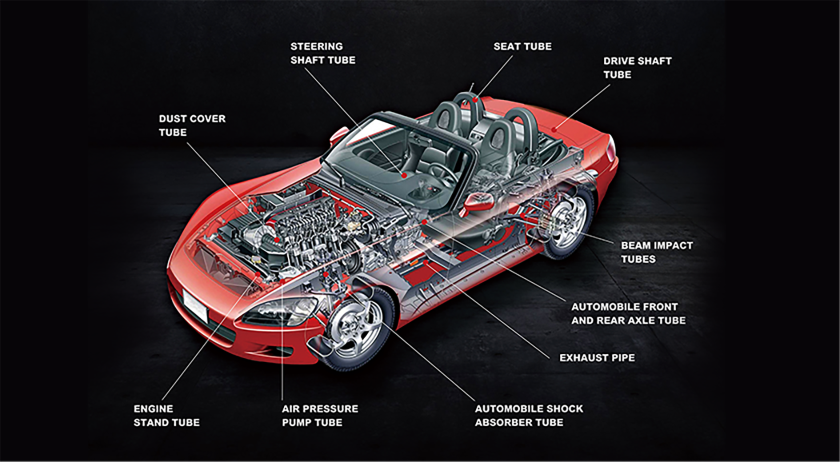

cnc motorcycle parts

cnc motorcycle parts. Once programmed, a CNC machine can produce the same part repeatedly without fatigue or inconsistency, unlike human operators. This not only speeds up production times but also lowers labor costs, ultimately making motorcycles more affordable for consumers.

The flexibility of CNC technology is another advantage. If a manufacturer needs to adjust a part's design or introduce a new feature, it's often as simple as updating the software program. This contrasts sharply with traditional manufacturing methods, which might require entirely new tooling and setup processes for even minor changes. As a result, CNC allows motorcycle companies to adapt quickly to changing market demands or customer preferences.

In conclusion, CNC motorcycle parts represent a cornerstone of modern motorcycle manufacturing. They ensure that each motorcycle is constructed with precision, reliability, and efficiency, traits that are paramount in today's competitive automotive landscape. As technology continues to evolve, one can only imagine the further advancements that CNC will bring to the motorcycle industry, ensuring that these beloved vehicles remain at the cutting edge of performance and style for years to come.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

These machines can operate continuously, 24/7, with minimal human intervention These machines can operate continuously, 24/7, with minimal human intervention

These machines can operate continuously, 24/7, with minimal human intervention These machines can operate continuously, 24/7, with minimal human intervention