Benefits of Using Structural Steel Tubing

1. Exceptional Strength-to-Weight Ratio

One of the most significant advantages of structural steel tubing is its impressive strength-to-weight ratio. Unlike traditional solid steel bars or plates, CBIES precision steel tubes provide significant structural support without the added bulk. This characteristic is particularly beneficial in mechanical equipment, where every ounce counts. Engineers can design lighter and more efficient machines that consume less energy and provide optimal performance while maintaining structural integrity.

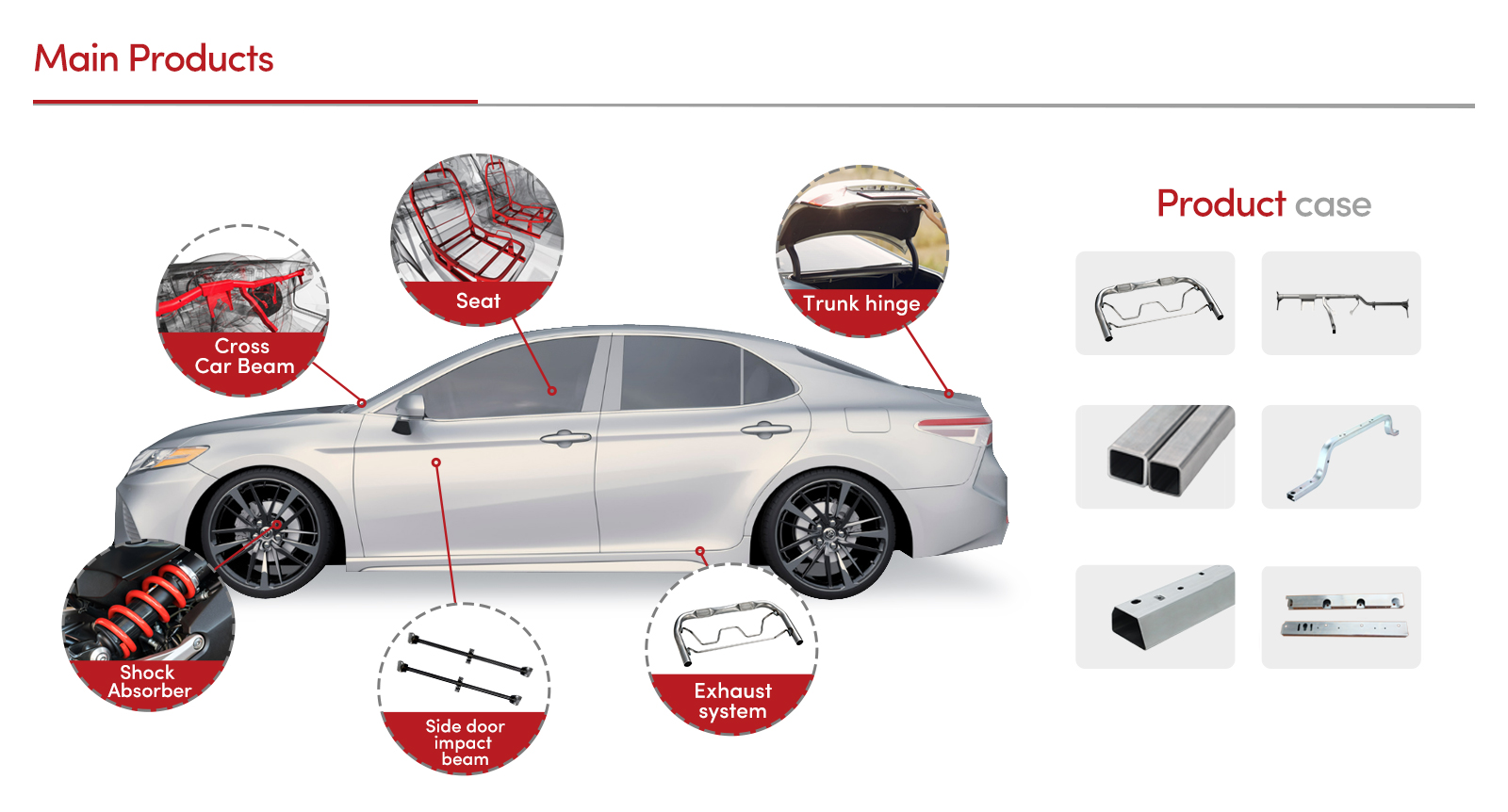

2. Versatile Applications

Structural steel tube is incredibly versatile, making it suitable for a wide range of mechanical applications. From 자동차 시트 프레임 to mechanical components, the adaptability of steel tubing allows it to meet various design specifications. Its ability to be easily welded, formed, and fabricated means that it can be utilized in custom solutions that meet the unique demands of different projects.

3. Enhanced Resistance to Environmental Factors

Steel tubing is known for its durability and resistance to environmental challenges. Unlike materials that may corrode or degrade over time, structural steel tubing undergoes treatments that increase its resistance to rust, corrosion, and impact. This resilience ensures that mechanical equipment remains operational for longer periods, reducing maintenance costs and downtime.

4. Economical Solution

Investing in structural steel tubing can also translate into significant cost savings for manufacturers and builders. The long lifespan, reduced maintenance needs, and lightweight nature of structural steel tubes can decrease operational costs significantly. Moreover, the efficiency of using pre-fabricated steel components can lead to faster assembly times, ultimately saving time and labor costs during the construction process.

5. Eco-Friendly Choice

In today’s world, the demand for sustainable construction materials is on the rise. Structural steel tube stands out as an eco-friendly option due to its recyclability. Steel is one of the most recycled materials globally, and using structural steel tubing contributes to a more sustainable lifecycle for mechanical equipment. By choosing this material, companies can reduce their carbon footprint and promote environmental responsibility.

6. Improved Aesthetic Appeal

Structural steel tubing is not just about functionality; it also brings an element of aesthetic appeal to mechanical designs. The sleek, clean lines of steel tubing can be incorporated into modern designs, enhancing the overall look of mechanical equipment. This feature is particularly valuable in industries where the visual impression of machinery can influence customer perceptions and brand image.

Comparing Structural Steel Tubes with Other Materials: Why Steel is the Best Choice

First and foremost, structural steel tubes possess exceptional strength-to-weight ratios. Unlike alternatives such as aluminum or plastic tubes, which may offer some resilience, steel provides unmatched robustness. This means that structures made from steel can bear heavier loads and stress, ensuring safety and longevity in various applications.

Moreover, precision steel tubes are engineered for accuracy, with tighter tolerances than many other materials. This precision is essential for projects that require exact measurements and quality finishes. Using precision steel tubes also reduces the need for additional machining and adjustments, which can lead to time and cost savings in the construction process.

Another advantage of structural steel tubes is their outstanding resistance to environmental challenges. Unlike wood or plastic, which can deteriorate over time due to moisture, pests, or UV exposure, structural steel tubes remain impervious to such threats, making them a more sustainable and low-maintenance choice.

Additionally, steel is infinitely recyclable, aligning with today's eco-conscious construction practices. Utilizing structural steel tubes contributes to a greener built environment, whereby waste is minimized, and resources are conserved.

So comparing structural steel tubes with other materials, steel emerges as the best choice due to its strength, precision, durability, and eco-friendliness. For any construction project, opting for structural steel tubes, particularly precision steel tubes, is not just a smart decision; it's a commitment to quality and longevity in structural integrity. Choose steel – choose excellence.

Different Types of Structural Steel Tubes

Structural steel tubes are an integral part in mechanical equipment, providing strength, durability, and versatility to a wide range of applications. Let’s delve into the various types available and their unique benefits.

HSS Steel Tubes

Hollow Structural Steel (HSS) tubes are favored for their high strength-to-weight ratio. They come in various shapes, including square, rectangular, and round, offering unmatched versatility. The design of HSS steel tubes means they can easily fit into different structural systems, making them suitable for everything from buildings to bridges.

Hollow Structural Tubes

Hollow structural tubes are cylindrical in shape, often used in applications requiring a lightweight yet strong solution. Their hollow design allows for easy integration into frameworks and supports, optimizing space and materials. This type of tubular steel is commonly used in scaffolding and various building frameworks.

Metric Structural Tubing

For projects requiring precise measurements, metric structural tubing is available. This type of tubing adheres to metric specifications, making it necessary for international projects. Designers and architects can efficiently incorporate these tubes into their plans, ensuring compatibility with global standards.

Rectangular and Round Structural Steel Tubing

Rectangular structural steel tubing excels in applications demanding greater rigidity, making it an ideal choice for structural frames. On the other hand, round structural steel tubing is favored for its aesthetic appeal and ability to handle torsional loads effectively, commonly used in railings, fences, and other architectural elements.

Shaped Structural Tubing

Shaped structural tubing refers to any non-standard cross-section, allowing for customized designs that meet specific project requirements. Whether it’s elliptical or another unique shape, shaped structural tubing provides creative freedom in architectural design.

아프리카 사람

아프리카 사람  알바니아

알바니아  암하라어

암하라어  아라비아 말

아라비아 말  아르메니아 사람

아르메니아 사람  아제르바이잔

아제르바이잔  바스크 사람

바스크 사람  벨로루시어

벨로루시어  벵골 사람

벵골 사람  보스니아어

보스니아어  불가리아 사람

불가리아 사람  카탈로니아 사람

카탈로니아 사람  세부아노어

세부아노어  코르시카어

코르시카어  크로아티아어

크로아티아어  체코 사람

체코 사람  덴마크 말

덴마크 말  네덜란드 사람

네덜란드 사람  영어

영어  에스페란토 말

에스페란토 말  에스토니아 사람

에스토니아 사람  핀란드어

핀란드어  프랑스 국민

프랑스 국민  프리지아어

프리지아어  갈리시아어

갈리시아어  그루지야 사람

그루지야 사람  독일 사람

독일 사람  그리스 어

그리스 어  구자라트어

구자라트어  아이티 크리올어

아이티 크리올어  하우사

하우사  하와이 사람

하와이 사람  헤브라이 사람

헤브라이 사람  아니요

아니요  먀오족

먀오족  헝가리 인

헝가리 인  아이슬란드어

아이슬란드어  이보

이보  인도네시아 인

인도네시아 인  아일랜드의

아일랜드의  이탈리아 사람

이탈리아 사람  일본어

일본어  자바어

자바어  칸나다어

칸나다어  카자흐어

카자흐어  크메르어

크메르어  르완다

르완다  한국인

한국인  쿠르드어

쿠르드어  키르기스어

키르기스어  결핵

결핵  라틴어

라틴어  라트비아 사람

라트비아 사람  리투아니아 사람

리투아니아 사람  룩셈부르크어

룩셈부르크어  마케도니아 어

마케도니아 어  말가시

말가시  말레이 사람

말레이 사람  말라얄람어

말라얄람어  몰티즈

몰티즈  마오리족

마오리족  마라티어

마라티어  몽고 어

몽고 어  미얀마

미얀마  네팔어

네팔어  노르웨이 인

노르웨이 인  노르웨이 인

노르웨이 인  옥시탄

옥시탄  파슈토어

파슈토어  페르시아 인

페르시아 인  광택

광택  포르투갈 인

포르투갈 인  펀자브어

펀자브어  루마니아 사람

루마니아 사람  사모아어

사모아어  스코틀랜드 게일어

스코틀랜드 게일어  세르비아 사람

세르비아 사람  영어

영어  쇼나

쇼나  신디어

신디어  신할라어

신할라어  슬로바키아 사람

슬로바키아 사람  슬로베니아

슬로베니아  소말리아어

소말리아어  스페인의

스페인의  순다어

순다어  스와힐리어

스와힐리어  스웨덴어

스웨덴어  타갈로그어

타갈로그어  타지크어

타지크어  타밀 사람

타밀 사람  타타르어

타타르어  텔루구어

텔루구어  태국어

태국어  터키어

터키어  투르크멘 말

투르크멘 말  우크라이나 인

우크라이나 인  우르두어

우르두어  위구르어

위구르어  우즈벡어

우즈벡어  베트남어

베트남어  웨일스 말

웨일스 말  돕다

돕다  이디시어

이디시어  요루바어

요루바어  줄루 족

줄루 족