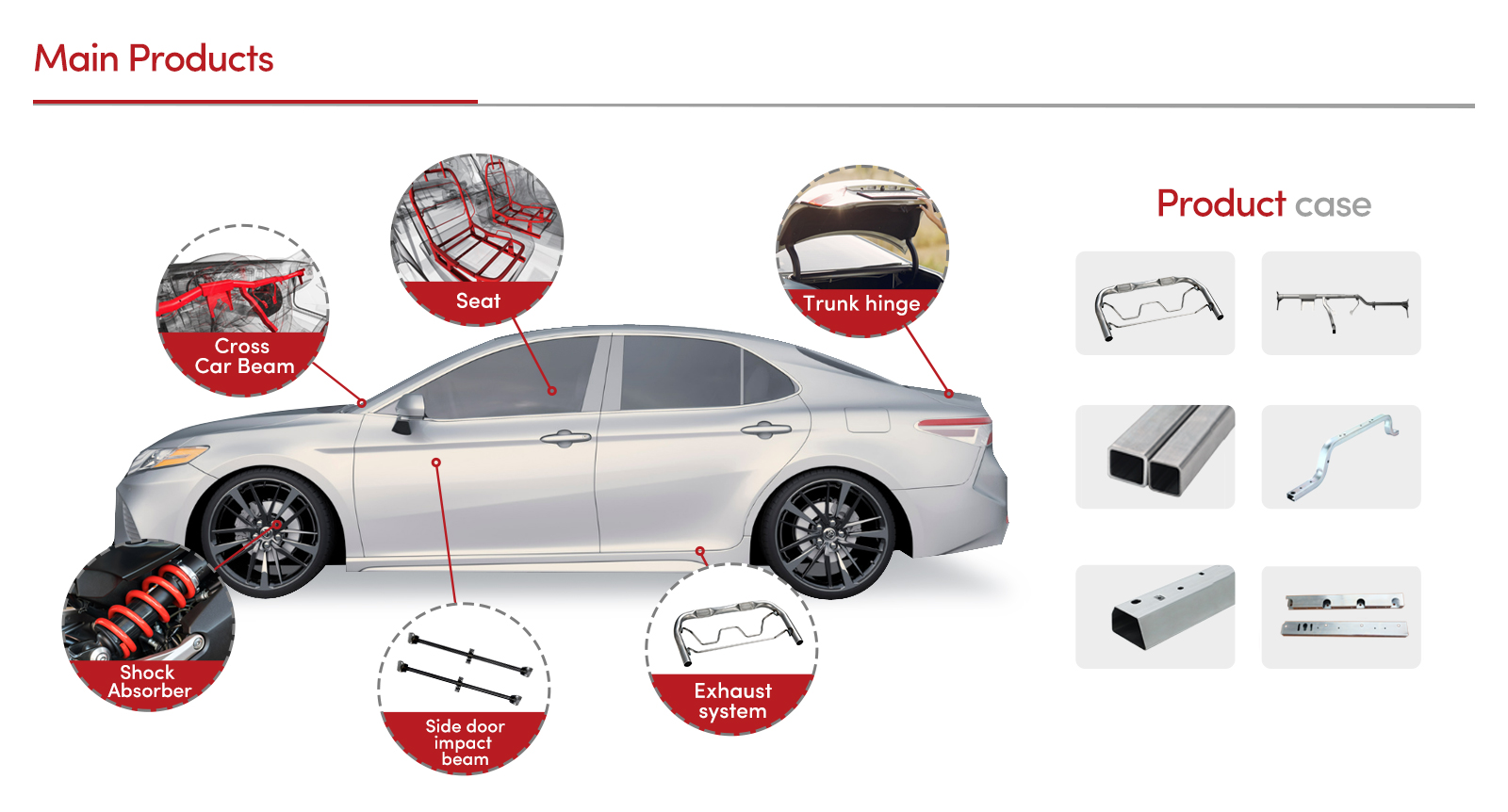

How Do Side Impact Bars Work

Side impact bars, also known as side impact beams or side intrusion beams, play a crucial role in automotive safety by providing structural support and protection during side collisions. These beams are strategically placed within the doors and side panels of vehicles to absorb and dissipate the energy from a crash, minimizing the risk of injury to occupants.

What Are Side Impact Bars?

Side impact bars are reinforced structures embedded in the doors and sides of a vehicle. They are designed to withstand high levels of force, thereby protecting the passengers inside.

How Do Side Impact Bars Function?

When a side collision occurs, the force of the impact is transmitted through the vehicle's body. Here’s how side impact beams work to protect the occupants:

Energy Absorption: Side impact beams are made from high-strength materials, such as automotive-grade hot-formed steel. This steel undergoes a transformation into an austenitic structure at high temperatures, followed by rapid cooling (quenching). This process significantly increases the strength of the steel to 1500 MPa or above, allowing the beams to absorb and dissipate a substantial amount of energy from the collision.

Energy Distribution: The beams help distribute the force of the impact across a wider area of the vehicle’s body, reducing the concentration of force on any single point. This distribution minimizes the deformation of the vehicle’s interior space, protecting the occupants.

Structural Integrity: Impact beams in cars are integral to maintaining the structural integrity of the vehicle. By preventing excessive deformation, these beams ensure that the passenger compartment remains intact, reducing the risk of serious injuries.

Minimizing Intrusion: Side intrusion beams are specifically designed to prevent objects or parts of the vehicle from penetrating the cabin during a collision. This is crucial in keeping passengers safe from external debris and other hazardous materials.

Materials and Design of Side Impact Door Beam

The effectiveness of side impact beams largely depends on the materials and design used. Modern side impact beams utilize advanced materials like hot-formed steel, which not only provides exceptional strength but also flexibility. This combination allows the beams to bend without breaking, absorbing more energy and providing better protection.

Side Door Beams Provide Protection

In the ever-evolving landscape of automotive safety, one component often overlooked is the hot-rolled steel tube. These vital structures serve as a critical line of defense, providing essential protection to vehicle occupants during side-impact collisions. As safety standards become increasingly stringent, understanding the integral role that side-impact door beams play can empower consumers to make informed decisions when purchasing a vehicle.

At first glance, the side impact door beam may not seem remarkable. However, this robust reinforcement is designed specifically to absorb and dissipate the energy generated during a side collision. Strategically placed within the vehicle’s door structure, these beams work in tandem with other safety features such as airbags and crumple zones to minimize injury risks. In fact, studies have shown that vehicles equipped with high-quality side-impact door beams significantly enhance occupant protection, making them a non-negotiable feature for any safety-conscious driver.

The engineering behind side-impact door beams is a testament to the advancements in automotive technology. Constructed from high-strength materials, such as steel or aluminum, these beams are designed to withstand extreme forces. Their placement within the door not only reinforces structural integrity but also reduces the likelihood of intrusion into the cabin during an accident. This protection becomes especially critical for families, who rely on these safety measures for their loved ones.

Moreover, the presence of side impact door beams is a clear indicator of a vehicle's commitment to safety. As consumers become more aware of automotive safety ratings, understanding features like these can influence purchasing decisions. Auto parts suppliers that prioritize the installation of superior side-impact door beams are setting a standard for safety that resonates with modern buyers.

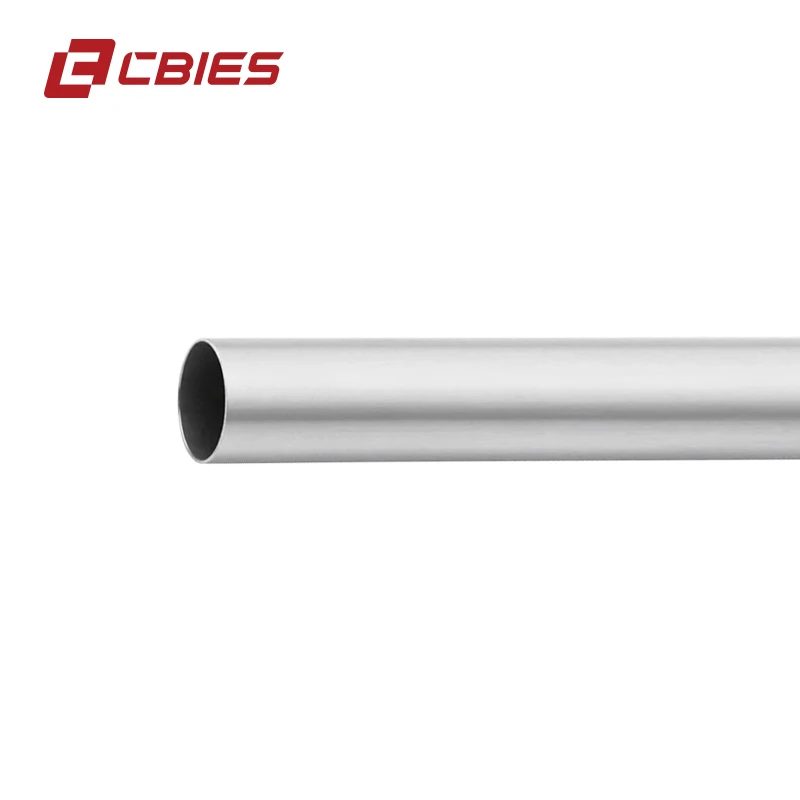

The Vital Role of Hot Rolled Steel Tubes in Automotive Safety

Hot-rolled steel tubes offer distinct advantages over other materials, making them a popular choice in the automotive sector. These tubes are produced at high temperatures, which ensures excellent ductility and toughness. As a result, hot-rolled steel tubes can easily withstand extreme pressures and impacts, making them ideal for the side-impact door beams that are integral to vehicle safety.

One of the key benefits of using hot rolled steel tubes in the construction of side-impact door beams is their ability to absorb shock effectively. In the event of a side collision, the energy generated is dispersed throughout the beam, minimizing the force transferred to the vehicle's interior. This energy absorption capability significantly reduces the risk of injury to passengers, thereby enhancing overall vehicle safety.

Moreover, hot-rolled steel tubes provide structural integrity while also allowing for design flexibility. Manufacturers can create complex shapes and configurations that not only bolster safety but also support aesthetic vehicle design. The strength and reliability of hot-rolled steel tubes enable engineers to focus on innovative designs without compromising safety standards.

Another important aspect to consider is cost-effectiveness. The production of hot rolled steel tubes is generally more economical compared to alternatives like aluminum or composite materials. This affordability allows car manufacturers to incorporate high-quality safety features, such as the side impact door beam, without inflating vehicle costs excessively.

In conclusion, the integration of hot rolled steel tubes in side-impact door beams exemplifies the commitment to safety in the automotive industry. These tubes not only enhance structural performance but also provide a reliable barrier between passengers and potential hazards on the road. As we continue to advance in automotive technology, the role of hot-rolled steel tubes will undoubtedly remain central in the quest for greater vehicle safety. Investing in these materials translates to a safer, more resilient driving experience for everyone.

Comparison: Precision Steel Tubes vs. Traditional Materials in Side Impact Door Beams

In the automotive parts wholesale industry, safety is paramount, particularly concerning side impact protection. When it comes to enhancing the integrity of vehicles during side collisions, the choice of materials for side-impact door beams plays a crucial role. Among the various materials available, Precision Steel Tubes have emerged as a superior alternative to traditional materials such as aluminum and conventional steel.

Strength and Durability

Precision Steel Tubes, known for their high tensile strength and durability, provide excellent protection against side impacts. Their ability to withstand deformation during a collision ensures that the vehicle’s occupants remain safe. In comparison, traditional materials may not offer the same level of resilience, often leading to inadequate protection in side impact scenarios.

Weight Efficiency

Another significant advantage of Precision Steel Tubes is their weight efficiency. These tubes are engineered to provide strength without the added weight, which is essential for modern automotive design. In contrast, traditional materials can be heavier, impacting a vehicle's fuel efficiency and handling. The aerospace-inspired design of Precision Steel Tubes allows manufacturers to create robust side-impact door beams that do not compromise the overall vehicle dynamics.

Cost-Effectiveness

Economically, Precision Steel Tubes can offer a more cost-effective solution in the production of side-impact door beams. While the initial investment in high-quality tubes may be higher, the long-term savings associated with reduced material usage, lower maintenance costs, and enhanced safety ratings can outweigh these initial costs. On the other hand, traditional materials often incur higher lifetime costs due to increased repairs from damage sustained during collisions.

In summary, when comparing Precision Steel Tubes to traditional materials for side-impact door beams, it becomes evident that the former presents numerous advantages. With superior strength, optimized weight, and appealing cost-effectiveness, Precision Steel Tubes are revolutionizing safety standards in automotive design. As vehicle manufacturers continue to prioritize occupant safety, the adoption of Precision Steel Tubes in side-impact door beams is likely to increase, paving the way for safer roads in the future.

How Precision Steel Tubes Improve the Durability of Side Impact Beams

Precision steel tubes play a crucial role in enhancing the durability and safety of side impact beams in automotive design. These beams are integral components of a vehicle’s safety structure, designed to absorb and dissipate energy during side collisions. The use of precision-engineered steel tubes significantly improves their performance in several ways.

Firstly, precision steel tubes are produced with strict tolerances and consistent wall thickness, ensuring uniformity and strength throughout the component. This uniformity allows for the efficient distribution of impact forces, minimizing the risk of failure at weak points. By utilizing high-strength steel alloys, manufacturers can create tubes that not only withstand greater forces but also maintain their integrity under extreme conditions.

Secondly, the lightweight nature of precision steel tubes contributes to the overall efficiency of the vehicle. Reducing weight is essential for improving fuel economy and handling without compromising safety. These tubes can be designed to maintain high strength-to-weight ratios, ensuring that side impact beams are both effective in energy absorption and lightweight, enhancing vehicle performance.

Additionally, precision steel tubes can be tailored in terms of geometry and cross-sectional design to optimize their energy absorption characteristics. By adjusting the diameter, wall thickness, and shape, engineers can create side impact beams that are better suited to specific crash scenarios, further improving passenger protection.

Lastly, the robustness and corrosion resistance of precision steel tubes ensure their longevity and reliability over time. This durability reduces the need for frequent repairs or replacements, ultimately leading to lower maintenance costs for vehicle owners.

In summary, the incorporation of precision steel tubes in side impact beams significantly enhances their durability and performance, providing greater protection for occupants in the event of side collisions while also contributing to overall vehicle efficiency.

africana

africana  albanès

albanès  amàric

amàric  àrab

àrab  armeni

armeni  azerbaidjana

azerbaidjana  basc

basc  Bielorús

Bielorús  bengalí

bengalí  bosnià

bosnià  búlgar

búlgar  català

català  Cebuà

Cebuà  Cors

Cors  croat

croat  txec

txec  danès

danès  holandès

holandès  Anglès

Anglès  esperanto

esperanto  estonià

estonià  finès

finès  francès

francès  frisó

frisó  gallec

gallec  georgiana

georgiana  alemany

alemany  grec

grec  Gujarati

Gujarati  crioll haitiano

crioll haitiano  hausa

hausa  hawaià

hawaià  hebreu

hebreu  No

No  Miao

Miao  hongarès

hongarès  islandès

islandès  igbo

igbo  indonesi

indonesi  irlandesa

irlandesa  italià

italià  japonès

japonès  javanès

javanès  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Ruandès

Ruandès  coreà

coreà  kurd

kurd  kirguis

kirguis  TB

TB  llatí

llatí  letó

letó  lituà

lituà  luxemburguesa

luxemburguesa  macedoni

macedoni  Malgashi

Malgashi  Malai

Malai  malayalam

malayalam  maltès

maltès  Maori

Maori  Marathi

Marathi  mongol

mongol  Myanmar

Myanmar  nepalí

nepalí  noruec

noruec  noruec

noruec  occità

occità  Pashto

Pashto  persa

persa  polonès

polonès  portuguès

portuguès  panjabi

panjabi  romanès

romanès  samoà

samoà  Gaèlic escocès

Gaèlic escocès  serbi

serbi  Anglès

Anglès  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  eslovac

eslovac  eslovè

eslovè  Somali

Somali  espanyol

espanyol  Sundanès

Sundanès  suahili

suahili  suec

suec  Tagalog

Tagalog  Tadjik

Tadjik  Tamil

Tamil  Tàrtar

Tàrtar  Telugu

Telugu  tailandès

tailandès  turc

turc  turcomà

turcomà  Ucraïnès

Ucraïnès  Urdú

Urdú  uigur

uigur  Uzbek

Uzbek  vietnamita

vietnamita  gal·lès

gal·lès  Ajuda

Ajuda  Yiddish

Yiddish  ioruba

ioruba  Zulu

Zulu